Technological Innovation

Innovation platform

HBIS Group focuses on new materials, new energy, new processes, green low-carbon and intelligent manufacturing, strengthens the deep integration of production, education and research led by enterprises, creates a "3+1" R&D system with resource coordination and smooth operation, and promotes high-quality development with technological upgrading. "3" means to build a three-level R&D system, a group-level R&D platform, aiming at the world's frontier, national strategy and market demand in key areas; The technical center of the subsidiary is focusing on technology iterative upgrading, efficiency and guarantee capacity building. The R&D unit of the factory department solves the cost reduction and efficiency increase of production lines, quality control, and model standardization. "1" is to build a global technology research and development platform, gather global intellectual resources, and build 39 global technology research and development platforms with world-class leading enterprises and well-known scientific research institutes for metal material research and development, process research, green and low-carbon development, intelligent upgrading and other fields.

R&D Center

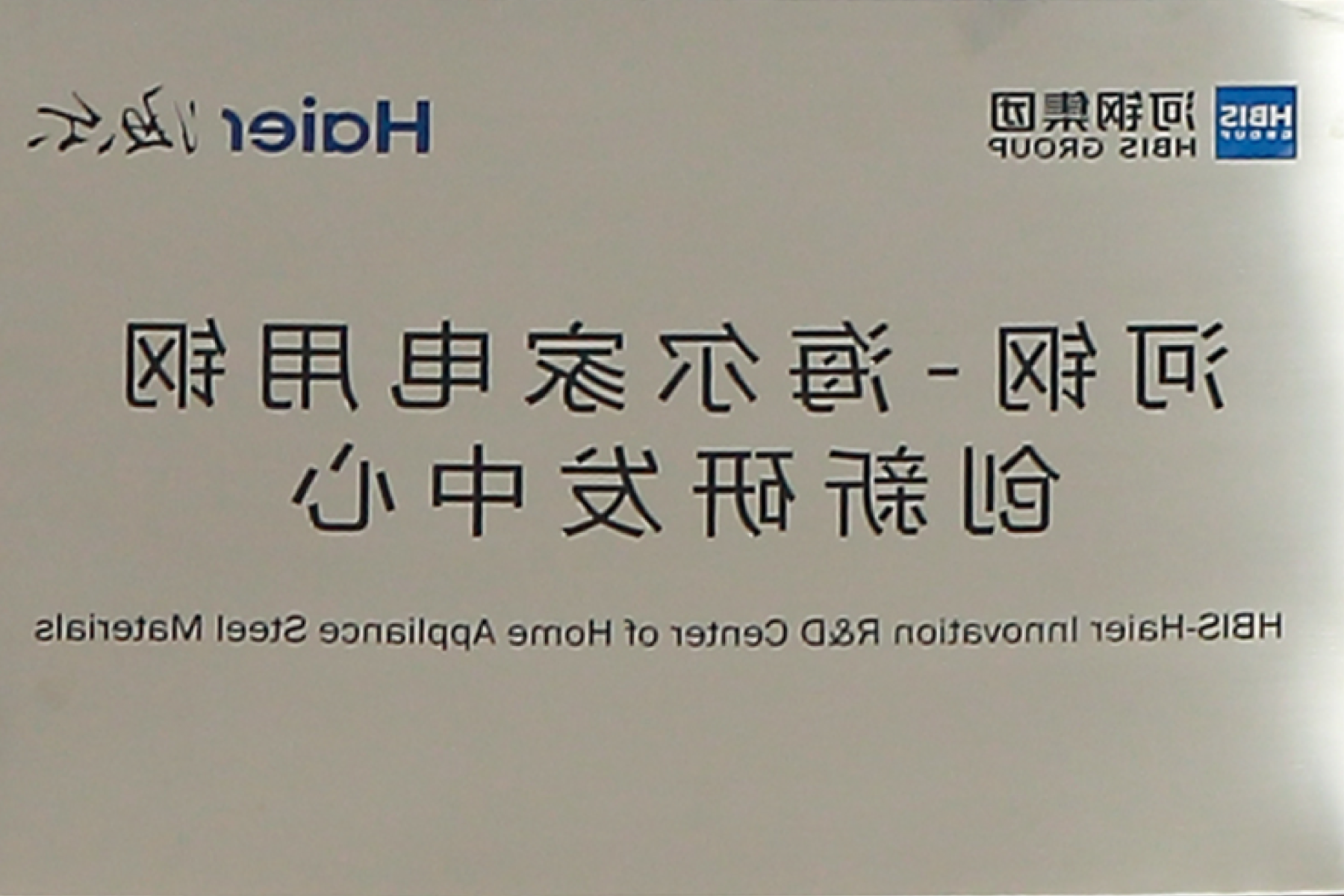

- User Materials Technology Research Center

- Sustainable Development Research Center

- Taihang Artificial Intelligence Research Center

- International Academic Exchange Center

- High-end talent training center

Taking the bottleneck problem of the industrial chain, the actual needs and future needs of users as the traction, it provides users with key common technical support for the whole chain from materials to applications. Establish and improve user service laboratories, material data centers, and user experience centers, with a complete set of technical service capabilities for the development and application of full-life cycle materials and form a scientific research system that obtains from user needs, orients material research and development, and precision technical services. Realize material breakthroughs, product substitution, technology leadership, construction market recognition, user-dependent technical service platforms and material incubation bases, as well as international first-class and domestic leading user technology research centers.

In the direction of strategic decision-making support, cutting-edge technology research and development, and upstream and downstream collaborative innovation, aiming at the key common frontier technologies of low-carbon and green in the steel industry, we will carry out special research on the "dual carbon" policy and research and development of pollution reduction and carbon reduction technologies, and promote the steady implementation of HBIS' carbon reduction technology path. Carry out low-carbon collaborative innovation of upstream and downstream enterprises, build a low-carbon industrial ecosystem centered on steel products, and build a low-carbon technology research and development and service platform with international vision, industry height and competitive advantage.

Fully grasp the opportunity of the industrial revolution brought by the new generation of information technology, develop intelligent technologies such as the Internet of Things, industrial Internet, blockchain, digital twin, big data and cloud computing, break through the bottleneck of intelligent manufacturing and the key technology of "stuck neck", and integrate digital and intelligent technology into the decision-making process of steel manufacturing and operation. Relying on HBIS Group's rich steel intelligent manufacturing scenarios and other industrial fields, promote process innovation, equipment upgrading, management optimization and intelligent production process. Create independent, controllable and secure digital technologies, form intelligent manufacturing system solutions based on artificial intelligence and other technologies, and empower the digital transformation of industrial enterprises.

Link global high-end talents and advantageous innovation resources in the steel industry, institutions and advanced enterprises, and carry out international academic exchanges, scientific and technological frontier releases, top talent introduction and other innovative activities. Promote the exchange of visits, mutual assignments and mutual introduction of high-end talents, build an academic exchange center with industry influence, and a top international scientific and technological innovation platform and enterprise think tank integrating international cooperation, academic exchanges, talent introduction and brand promotion.

Relying on HBIS Group postdoctoral workstation, academician workstation and other talent incubation platforms, based on HBIS Group' s sufficient human resource reserves and rich application scenarios, promote HBIS Group's strategic key talent construction projects, construct a supporting system for talent development, build a high-end talent training platform, and continuously explore a systematic talent training mechanism for talent introduction, cultivation, use and promotion.

Key technologies

It has formed the whole process of steel production and manufacturing technology such as mining, ironmaking, steelmaking, rolling and deep processing.Cleaner production technology

Implement advanced pollutant control technologies covering source reduction, process control and end treatment, such as sulfur reduction based on blast furnace charge structure optimization, energy saving and emission reduction of sintering flue gas cycle, multi-process multi-pollutant ultra-low emission control, etc. It is supporting atmospheric pollutant emission indicators that are comprehensively better than ultra-low emission standards. Develop and apply the water and salt collaborative control and resource system with urban water as the water source, coupled with the water film cold peak shaving high-efficiency air cooling system, concentrated salt moisture and salt crystallization resources and other key water-saving and salt control technologies. Finally achieve low-cost wastewater zero discharge, creating a model of harmony and co-prosperity with the urban water environment. Develop key technologies for the utilization of waste heat and energy, such as efficient integration of coking energy flow, low-pressure waste heat steam power generation and steel slag modified gas quenching treatment, and break through the problem of low-temperature, intermittent and dispersed low-temperature waste heat recovery. Develop a comprehensive utilization technology system for the collaborative disposal of typical solid and hazardous waste of iron and steel, integrate "harmless, reduce and recycle" technologies such as ultrafine powder building materials, efficient coordination of medium and low-grade zinc-containing solid waste resources, and preparation of all-solid waste cementitious materials, realize the resource utilization of metallurgical solid waste "turning waste into treasure", and contribute steel power to the construction of a "waste-free city".

Coke dry quenching

Green mine development technology

In the whole process of mineral resources development, through the implementation of key technologies such as nano-scale atomization blasting dust reduction, full-particle level wet preselection, and green filling of tailings, a safe and environmentally friendly intelligent management and control platform has been created, which has realized the mine with ecological environment, scientific mining methods, efficient resource utilization, digital management information and harmonious mining community in the mining area.

The giant mine warrior KY-321A rotary drilling rig

Hydrogen metallurgy technology

Achieve hydrogen-based shaft furnace direct reduction technology, coke oven gas self-reforming technology, hydrogen-based shaft furnace process CO2 removal and efficient utilization technology, hydrogen-based shaft furnace process pollutant ultra-low emission technology. The successful commissioning of the world's first 1.2-million-ton hydrogen metallurgy demonstration project has led the industry to transform from "carbon metallurgy" to "hydrogen metallurgy", opened the era of hydrogen metallurgy and boosted the low-carbon green transformation.

hydrogen metallurgy demonstration project

Low-carbon and low-cost ironmaking technology

Develop all-oxygen hydrogen-rich carbon cycle reduction melting iron smelting technology, blast furnace hydrogen-rich low-carbon smelting technology, pellet extraction silicon reduction technology, high proportion pellet smelting technology, closed material yard technology, thick material layer sintering technology, sintering flue gas selective circulation technology, multi-process multi-pollutant ultra-low emission control technology, full-process ore blending model, blast furnace big data model. The application of low-carbon and low-cost ironmaking technology drives the green, sustainable and high-quality development of steel, helping to achieve the dual carbon goal.

3200 m³ blast furnace

Clean steel platform technology

The whole process and information integration platform of clean steel is constructed, and technologies such as analysis-optimized molten iron pretreatment, high-efficiency-enhanced converter smelting, rapid-coordinated secondary metallurgy, high-efficiency-constant speed full continuous casting, dynamic-orderly operation of informatization, fine-strict process parameter control and traceability are implemented, and realize the dynamic control of the cleanliness of molten steel in the whole process of steelmaking. A deep-drawn steel plate represented by HBIS GroupTangsteel and HBIS Group Hansteel, a special steel bar represented by HBIS Group Shisteel and a wide and thick plate clean steel platform system represented by HBIS Group Wusteel have been established.

VD vacuum refining

Automated steelmaking technology

Using flue gas analysis, auxiliary lance, big data and other technologies, it realizes accurate prediction of carbon and temperature in the whole process of converter blowing and stable control of the end point of blowing, promotes the organic penetration of automatic iron mixing, automatic blowing in the whole process, automatic steel tapping and automatic slag protection furnace, nests online intelligent evaluation models for cost and quality, and the intelligent control level of converter steelmaking has reached the leading level in the industry.

BOF master control room

Extra thick plate production technology

Clean steel smelting, electroslag remelting, micro-alloying, special ingot mold design, thick slab (ingot) efficient heating, extra thick plate rolling and extra thick steel plate roll quenching and other perfect production technology of extra thick steel plate can produce the maximum thickness of 700mm, and the product quality has reached the international leading level.

large steel ingot production

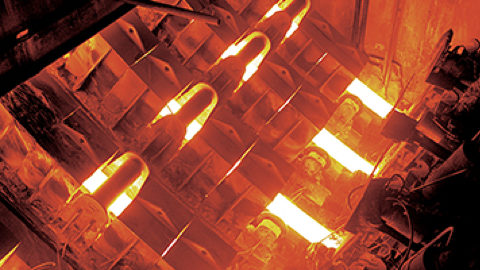

Ultra-thin hot-rolled coil production technology

Based on the continuous casting technology of high-tensile thin slab, the regenerative combustion technology of roller-bottom heating furnace and the automatic control technology of double-station hot coil box, the automatic leveling technology of strip tail plate type is stably applied to realize the batch and stable production of thin specifications of special varieties such as high-carbon steel, weathering steel, electrical steel, and construction machinery steel.

1810mm hot rolled coil production line

High-end automotive steel production technology

It integrates process technologies such as high cleanliness, narrow composition precise control, high-precision cold-rolled plate shape control, high-surface galvanized outer plate quality control, differential rapid jet cooling, precise organization regulation, high hydrogen cooling, and stable production of water quenching dual processes, etc., to realize the mass production of high-end automotive steel such as O5 grade automotive outer panels, ultra-deep drawing steel, and 2000MPa grade ultra-high strength steel, and "full vehicle manufacturing" of multiple models.

Rectangular continuous casting bloom production

High-end special steel bar production technology

Relying on the short-process production process, equipped with the world's largest section and deepest continuous die casting machine and the world's largest bar KOCKS three-roll reduced diameter rolling mill, applied with high-end bearing steel low titanium, low oxygen content control technology, high-end gear steel narrow composition, narrow hardenability control technology, high-end spring steel high cycle fatigue life control technology, high-end non-quenched and easy-cut steel high Al, N, S control technology, to meet the requirements of special steel bars for automobiles, rail transit and construction machinery.

Non tension rolling

Clean and efficient production technology of vanadium and titanium high-end products

In view of the problems of low vanadium extraction rate, inability to extract chromium, and high cost of high-salt ammonia nitrogen wastewater treatment in the traditional "vanadium slag sodification, roasting and vanadium extraction" process, a new generation of all-wet vanadium extraction technology with independent intellectual property rights was developed, and the world's first vanadium slag sub-molten salt method high-efficiency vanadium extraction clean production demonstration project was built, and a new green manufacturing process of high-purity vanadium oxide by ion displacement method and high-efficiency dissolution-targeted impurity removal-cascade reduction-electrochemical precise regulation of valence vanadium electrolyte was developed. The product wins the national manufacturing single champion product of the Ministry of Industry and Information Technology. It has realized the whole process of vanadium extraction and environmental protection, leading the green and high-end upgrading of the international vanadium chemical industry

Large blast furnace for V-Ti magnetite smelting